Connectors Used With Flex Rigid PCBs

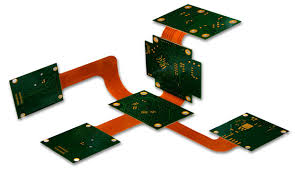

Rigid-flex PCBs are a popular choice for electronic devices that need the flexibility of flex circuitry. Compared to rigid boards, these circuits are highly space-efficient and can be bent or folded to fit in tight spaces. They are also durable and can withstand mechanical stress, vibrations, and temperature variations. They also feature fewer connectors, which reduces their proneness to failure.

Connectors are essential components that are required in the assembly of printed circuit boards. These are used for signal and power transmission between components on the board. The most common types of connectors include crimp connections, pin headers (standard, walled, with locking), and built-in self-stripping connectors. They are easy to assemble and provide excellent heat dissipation, allowing them to work in high-temperature environments.

Depending on the application, it is important to select the right type of flex rigid pcb for your project. There are a number of factors to consider, including the stack-up, thickness of FR4, and surface finishing options. Choosing the best thickness will help minimize cost while still providing the necessary structural integrity and reliability. It is also crucial to ensure that the traces are routed perpendicular to the bend line, as this helps prevent breakage during bending and folding.

Types of Connectors Used With Flex Rigid PCBs

Another factor to consider is the design for manufacturability of a flex-rigid PCB. This process involves analyzing the circuit design and selecting a fabrication house or manufacturer that will be able to meet your requirements. There are many different standards that must be followed, including signal integrity, mechanical, thermal, and electrical requirements. During the design phase, it is also important to keep in mind that the manufacturing process for rigid-flex and flex-rigid PCBs is very different from that of traditional rigid boards.

In general, any connector system that can be attached to a rigid-board can be attached to a flex-rigid board as well. However, the system must be designed with a localized stiffener in place to support the connector and add structural stability to the flex-rigid circuit.

A popular choice for a flex-rigid PCB is the ZIF connector. This is a single-part connector that is soldered directly to the rigid board. This method saves time and money as it eliminates the need for connector assembly on the flex circuit. Additionally, it provides a stable connection to the flex-rigid circuit and can handle higher current levels than conventional rigid-board connectors.

Using a unified design platform that allows you to work with MCAD and ECAD tools in 3D, makes designing a rigid-flex pcb much easier. By working with these tools in a single software program, you can easily determine the appropriate bending region for your flex circuit and generate design deliverables like Gerber files, assembly drawings, and more. The unified design model in Altium Designer makes it easier than ever to prepare your flex-rigid PCB for manufacturing and produce high-quality results.