importance of fiducial marks in Printed circuit assembly services

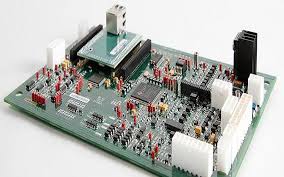

Fiducial marks play a pivotal role in Printed Circuit Assembly (PCA) services, serving as reference points that enable precise alignment and registration of PCBs and components throughout the assembly process. These small, strategically placed markers provide essential visual cues for assembly equipment, such as pick-and-place machines and solder paste printers, ensuring accurate placement of components and solder deposition on the PCB. The importance of fiducial marks lies in their ability to improve assembly efficiency, minimize errors, and enhance overall product quality in electronic manufacturing.

One of the primary functions of fiducial marks is to facilitate accurate component placement during PCB assembly. Modern electronic devices feature increasingly dense and complex PCB layouts, with components packed closely together and placed on multiple layers. Fiducial marks help assembly equipment identify the precise position and orientation of the PCB relative to the component placement head, enabling the machine to align components with the corresponding pads on the printed circuit assembly services with high precision. This ensures proper electrical connections and prevents misalignment errors that can lead to defective solder joints and assembly rework.

Furthermore, fiducial marks are essential for ensuring consistent solder paste deposition during the solder paste printing process. Solder paste printers use fiducial marks as reference points to align the stencil with the PCB accurately. By aligning the stencil and PCB with sub-micron precision, fiducial marks ensure uniform deposition of solder paste on the pads, minimizing variations in solder volume and improving solder joint quality. This precision is critical for achieving reliable electrical connections and mechanical stability in PCB assemblies, particularly for fine-pitch components and high-density PCB designs.

Can you explain the importance of fiducial marks in Printed circuit assembly services?

Moreover, fiducial marks play a crucial role in supporting automated optical inspection (AOI) and solder paste inspection (SPI) systems used for quality control in PCB assembly. AOI and SPI systems rely on fiducial marks to establish a coordinate system for inspecting solder joints, component placement accuracy, and overall assembly quality. By analyzing fiducial mark positions relative to the expected coordinates, these inspection systems can detect defects such as misaligned components, solder bridging, insufficient solder paste volume, and solder balling. This enables manufacturers to identify and rectify quality issues early in the assembly process, improving product reliability and reducing the risk of field failures.

Additionally, fiducial marks contribute to the traceability and documentation of PCB assembly processes. By including fiducial marks on PCB designs and assembly drawings, manufacturers can create a standardized reference system for tracking and documenting assembly-related information, such as component placements, solder paste volumes, and inspection results. This traceability not only facilitates quality assurance and process optimization but also supports compliance with industry standards and regulatory requirements, ensuring transparency and accountability in electronic manufacturing operations.

In conclusion, fiducial marks play a vital role in Printed Circuit Assembly (PCA) services by enabling precise alignment, accurate component placement, uniform solder paste deposition, quality control, and traceability. These small reference markers are essential for optimizing assembly efficiency, minimizing errors, and enhancing overall product quality in electronic manufacturing. As PCB designs become increasingly complex and assembly processes more automated, the importance of fiducial marks as a fundamental aspect of PCB assembly cannot be overstated. Their strategic placement and reliable functionality ensure the success and reliability of modern electronic devices.